just_a_hunter

Active Member

- Messages

- 471

Lets see some of your knives.

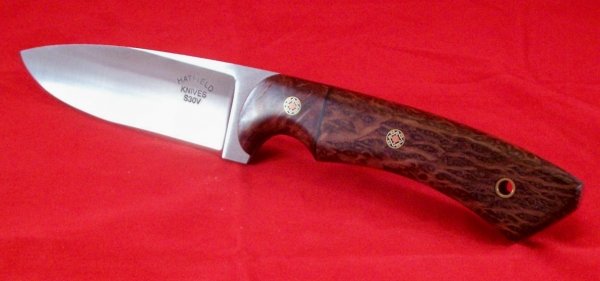

I'm a knife maker and thought I would share a few of mine. Just to clearify, I am not a custom knife maker, just a knife maker and none of these are for sale. I'm not trying to pimp my knives as I make very few of them. Just wanted to show them off I guess but I love knives and would also appreciate seeing some of yours.

Hand made or not, post what you got!

Todd

I'm a knife maker and thought I would share a few of mine. Just to clearify, I am not a custom knife maker, just a knife maker and none of these are for sale. I'm not trying to pimp my knives as I make very few of them. Just wanted to show them off I guess but I love knives and would also appreciate seeing some of yours.

Hand made or not, post what you got!

Todd